Commercial Service, NY Elevator Maintenance & Repair

Island Elevator provides a full line of commercial elevator repairs and service for Long Island, New York

Free Estimates

Commercial Elevator Applications Include:

Elevators Intended for Passengers

Passenger Elevators

Designed primarily for the safe transportation of people and their hand maneuvered items or equipment

We can provide elevators that seamlessly blend into your location and environment and design elevators that have a lasting first impression of your business or living experience.

Elevators Intended for Freight

Freight Elevators

Most often used when you need an elevator that can withstand heavy commercial or industrial work conditions. These elevators are designed to a higher level of resiliency when you need to transport heavy or oversized loads.

We specialize in freight elevators used in residential buildings, commercial warehouses, Hotel freight, and office building needs.

Freight elevators typically travel at a slower speed compared to passenger elevators and are usually designed with vertically opening doors.

Elevators Designed for Service

Service Elevators

This category of elevator falls in between transport for passengers only to passenger plus equipment or goods.

Service elevator systems include elongated passenger cars and are typically found in employee only areas of shopping centers, hospitals, hotels, apartment buildings, and other commercial locations.

Components of Commercial Elevator Types

MRL Elevators (Machine Room Less)

MRL Elevator Systems

These type of commercial elevators do not require a machine room and operate on either traction or hydraulic for their main drive.

MRL elevators require less energy to operate and opens up more space in your building for other needs.

Hydraulic Elevator Systems

Hydraulic Driven Elevators

Elevators with a hydraulic systems have a fluid driven piston mountain inside of a cylinder that lifts the elevator cab.

This type of elevator has benefits for low rise buildings that are typically no more than five levels in height.

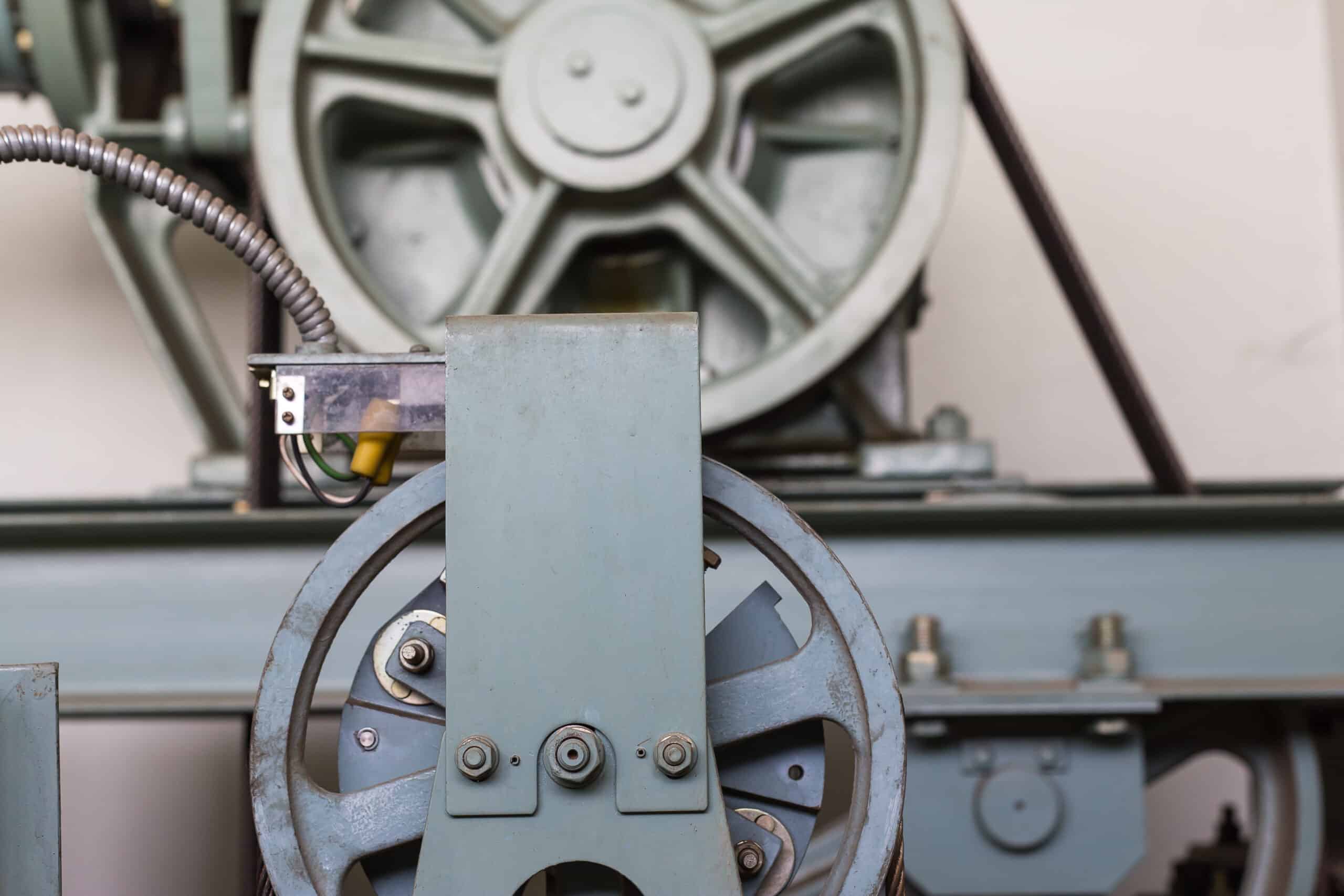

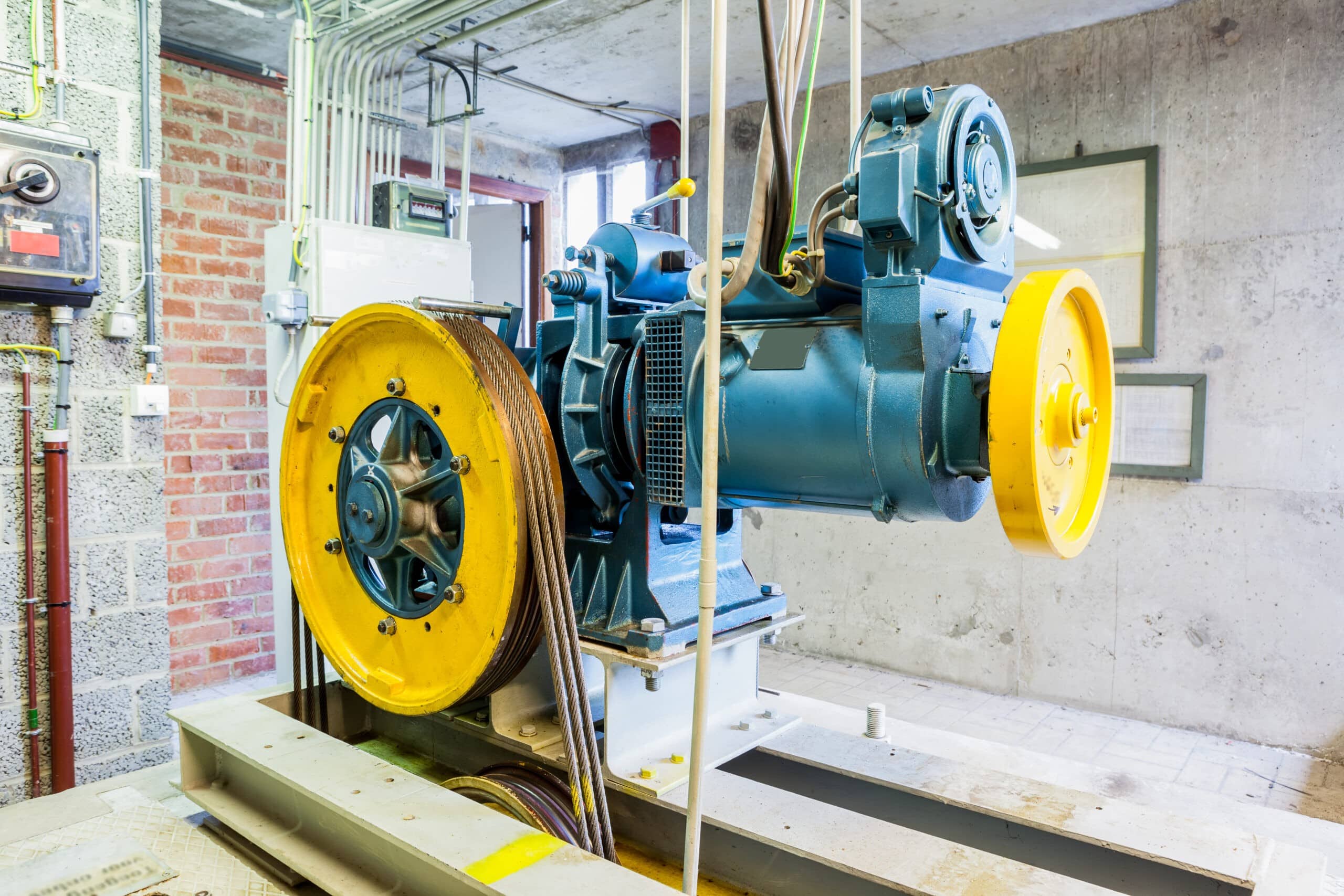

Traction Elevator Systems

Traction Elevator Limits

Traction elevator systems are found in mid to high rise building structures.

This type of system uses steel ropes to operate and raise or lower the cab within a traction designed elevator.

Manufactures & Suppliers

- GAL Manufacturing

- Elevator Controls Corp

- Virginia Controls

- Innovation Industries

- Claddagh Controls

- Monitor Controls

- Draka Elevator

- K-tech Phones

- Dura Lift

- Elevator Systems Inc

- Matot Elevator

- Waupaca Elevator

- Inclinator

- Alliance Elevator Solutions

- Motion Controls

- Vertical Express

- Canton Elevator

- Custom Elevator

- MEI Total Elevator Solutions

- EMI Porta

- Imperial Motors

- Titan Machine

- Maxton Manufacturing

- Elevator Equipment Corporation

- Blaine Valve

- Savaria Elevator

- Giant Elevator

- Autoquip

- Dover Elevator

- Westinghouse Elevator

- Othompson Elevator

- Sedgewick

- Concord Elevator

Fujitec NO

Pine State NO

Save Your Money

Our Budget friendly maintenance programs provide the attention your unit needs and peace of mind you desire. If you are using a large elevator company, you are paying too much!

Prevent Aggravation

We appreciate the importance of your elevator to your home and business. A shutdown can reduce productivity and effect the quality of life for people who rely on its operation.

Save Your Equipment

From construction to service, repair and maintenance, our highly trained and educated mechanics exercise the meticulous attention to detail necessary to extend the life and dependability of your equipment.