Multi-Unit Building Elevators, Luxury Apartments, Condo, Co-op

Luxury apartment building elevators can increase access to the units and result in higher revenue for the owner.

read article

Elevators are complicated systems and we can help to explain the different types of commercial elevators and their respective operations.

Looking back into history it used to be dangerous to ride an elevator. During the mid 1800’s several buildings and structures were being constructed with higher levels and elevators became a common item. Elevators gained significant design safety with a device that could prevent a passenger elevator from falling if its rope broke with a mechanism created by Elisha Otis. Soon, nearly all building designs were expected to have more than a single access point to a floor of a building. This became a standard to have access to building floors along with a standard staircase.

The six variations of elevators utilized in many buildings are as follows:

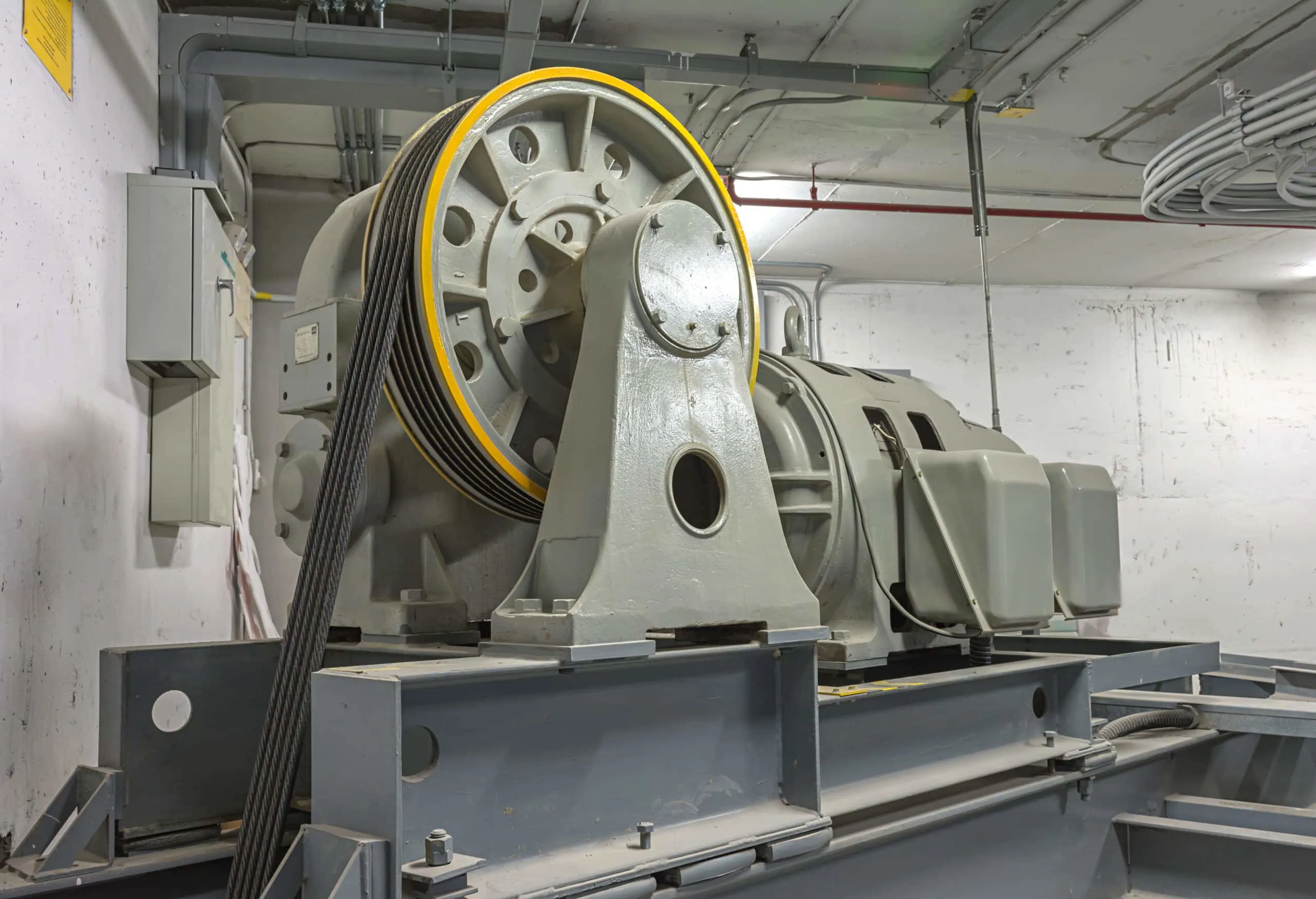

These types of elevators such as geared and gearless traction use ropes to lift them. The rope passes over a sheave attached to an electric motor that is located on top of the elevator shaft. These are common in midrise to high rise elevators and typically have faster travel times than hydraulic elevators.

The elevators will utilize a counter weight to help them run more efficiently by offsetting the load inside the elevator car that may consist of passengers weight or equipment. The elevators utilizing geared traction will use a gearbox that is attached to a motor. The gearbox purpose is to drive the sheave and operate the ropes. The geared traction elevators may have the ability to move up to 500 feet per minute. Travel distance for a geared traction elevator is around 250 feet.

Gearless traction elevators have a sheave that is directly attached to the motor. Typically gearless traction elevators have a higher price point for the initial cost of installation. Maintenance cost on a gearless traction elevator may stay consistent since they are often more efficient than geared traction elevators.

Inspecting traction of the elevator sheaves and ropes for wear and tear on a regular basis is vital. These items such as cables and sheave may wear down and cause slipping and reduce traction of the elevator components. This can reduce the efficiency of the elevator and increase the danger of using the elevator.

There is a restriction on height with traction elevators since they are designed with a specific length of rope, cable, and weight. New materials such as carbon fiber used with traction elevators help make them stronger and lighter and achieve new heights.

Machine Room-Less Elevators is a traction elevator that does not have a machine room over the elevator shaft. The machine room is typically located in another space and can be accessed through the cab near the top of the elevator for repairs. The control room hosts the control boxes and is typically on the highest landing adjacent to the elevator shaft.

Machine room less elevators have a maximum travel distance of 250 feet that may boast speeds up to 500 feet per minute. The MRL elevator has similar startup and maintenance cost as with geared traction elevators, but the MRL elevator will have lower energy cost than a geared elevator. MRL elevators are very popular for mid-rise buildings which require travel distances of 250 feet or less.

One of the major factors in the US is the slow adoption of MRL elevators is due to building codes. The provisions are in regards to the motor and location within the hoist way of the elevator. The building codes are changing and best practice is to check with your local code enforcement regarding MRL types of elevators.

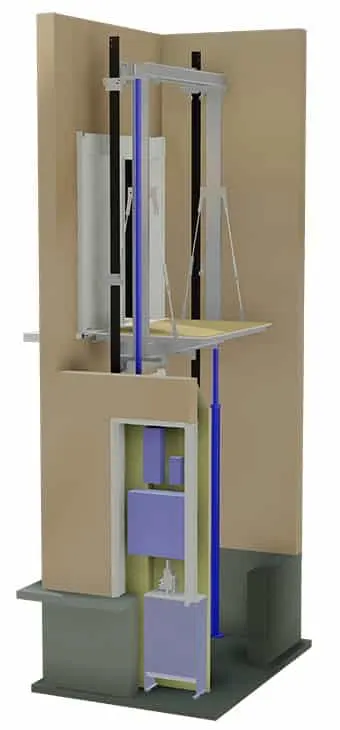

The design of a hydraulic elevator includes a piston that is found at the base to support it. The piston utilizes hydraulic pressure to push the elevator upwards in sync with a motor that manages oil (hydraulic fluid) within the piston. There is a speed valve that operates to relieve pressure inside the piston when the elevator descends.

Typically these elevators are only used in buildings that are limited to 8 floors or less and travel speeds average 150 feet per minute.

The machine room will typically be on the lowest level across from the elevator. The hydraulic elevator will have a piston that extends underneath the elevator floor inside the pit. When the elevator descends the piston retracts. There are different variations but most will have a telescoping piston that will collapse and requires only a shallow hole within the pit.

The hydraulic elevator travel distance is approximately 60 feet and may have a piston on either side of the cab if it is designed without a hole in the pit. Telescoping pistons may allow the elevator to travel 50 feet, whereas a non-telescoping piston may only rise up to 20 feet.

Compared to other elevators the initial cost and maintenance cost may be lower but the hydraulic energy cost can be higher. This is due to the electric motor operating heavily against gravity while forcing hydraulic fluid into the piston. One of the downsides to hydraulic elevators is the potential for fluid to leak and hazards to the environment.

Pneumatic elevators are raised and lowered by air pressure within the shaft. The air pressure difference is created between the above area and below area of the elevator cab. This creates a vacuum that transports the elevators by air physics. The elevator is operated by turbines or a vacuum pump which pulls the elevator up and releases pressure to allow the elevator to descend. Pneumatic elevators are compact by designed and good fit for residential elevator applications. There is no need for a hoist way or excavate pit to install pneumatic elevators.

This type of elevator is commonly used within construction or commercial work areas. Most of these elevators are driven under its own power device, which are electric or combustion powered. Temporary climbing elevators are commonly used within construction of high-rise buildings to move personnel and material before a permanent elevator is installed.

The industrial elevator is designed to hoist/lift extremely heavy weight and is typically used in construction, warehouses, and shipyards. They are designed to withstand extreme conditions in some of the world’s most hostile environments. Custom height requirements and quality material are used to construct industrial elevators to withstand heavy-duty usage.

Island Elevator is here to help you understand all facets of your Elevator Repair, Maintenance, & Modernization costs in the new year. Our team is here to help ensure your home and business vertical transportation equipment receive the regularly scheduled maintenance necessary to help you avoid a major catastrophe, reduce the possibility of a costly repair, and ensure the safety of your passengers, tenants, and family.

Luxury apartment building elevators can increase access to the units and result in higher revenue for the owner.

read article

Elevators are the lifelines of modern buildings, and routine maintenance is crucial to their ...

read article

When it comes to elevator repair, businesses need a reliable and experienced ...

read article

get a free estimate