The journey of one thousand miles begins with one step. Or, maybe, one elevator ride.

After an elevator installation, the system can run for 20 to 30 years. But an elevator system requires constant maintenance.

If one part breaks, the entire elevator can stop. Riders can get trapped inside and businesses within a building can suffer from delays.

There are a few common problems that can cause a breakdown. Identify them and you can repair your elevator in no time. Here is a quick guide.

1. Bearing Malfunction

A bearing is a part of your elevator motor. It allows the motor to turn without generating friction or losing energy to heat.

Bearings can roll loose, straining your motor. Your motor can start to shake, which can damage the motor further. If the bearings themselves get damaged, they can vibrate and wear your motor down.

To tell how your bearing is malfunctioning, listen to what sound it makes. If it makes a buzz or roar, it can have a number of problems. It may be deformed, or it may not fit over its shaft.

If it makes a screeching noise, its radial clearance is too large. Clearance is the distance that one ring moves relative to the other. When the distance is too far, the motor may not be able to turn properly.

If the bearing makes a crunching sound, the bearing is deformed. An elevator maintenance service will need to fix it for your elevator to work.

Most malfunctions will require replacements. If the bearing rolls loose, you may need to reinstall the entire motor so parts cannot roll free.

2. Contamination

As your motor wears down, it releases small metal particles. These particles enter the motor oil, causing the motor itself to stall.

Contamination can present in a few different ways. If you notice a sudden and foul odor, it might be from your motor. If the elevator struggles to move up and down, the motor may be contaminated.

Lubrication can also lead to contamination. If you use the wrong lubricant, particles in it can clog your seals.

To determine if you have a contamination problem, you need an oil analysis. Test oil samples throughout the elevator system.

High levels of bronze usually indicate wear in your elevator gears. High levels of aluminum can indicate wear in your elevator pump.

Determine where contamination could come from. Substances can leak from your elevator shaft into your system.

3. A Misaligned Motor Drive

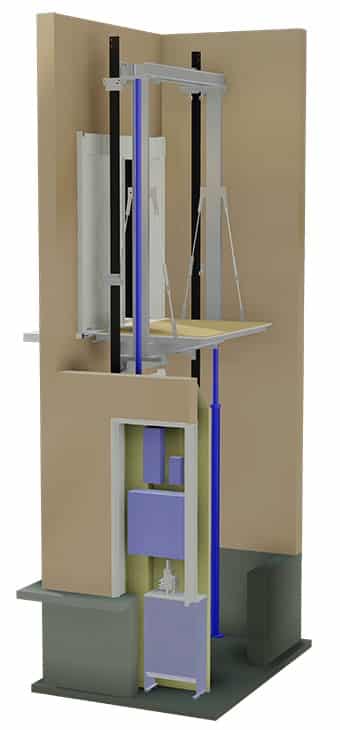

Your motor drive controls the speed of your elevator. Elevator installation companies place the drive directly onto the motor.

Small misalignments can cause problems. Your drive can knock your bearings loose. Your drive can speed the motor up too fast, increasing wear and tear.

If your elevator speeds up or slows down, your motor drive may be misaligned. If you cannot change the speed of your elevator, your drive is malfunctioning.

A misaligned drive is an essential repair. If you let your elevator operate with a misaligned motor, the motor will eventually break.

Keep a close eye on your drive. Use a straight edge and string to assess if it is aligned with the motor.

If it is misaligned, stop your elevator immediately. Call a maintenance service that can realign your drive directly onto the motor.

4. Power Failure

A power failure is perhaps the most distressing elevator problem. Several things can occur when the power to an elevator shuts off.

Lights can flicker and shut down. Doors can fail to open or close. The elevator can become stuck between floors, trapping passengers inside.

A power failure can occur as a result of an electrical outage. Some elevators have a battery system, so they can operate while an outage occurs.

To minimize the risk of getting stuck, encourage employees to take the stairs during an outage. Install signs that tell people what to do in the event of an emergency.

If your elevator gets stuck, contact emergency services. Go to where the elevator is and communicate with the passengers inside. Keep them calm until personnel arrives.

A malfunctioning motor can also cause a power failure. A dramatic change in voltage can seize a motor and cause lights to fail.

Conduct a power survey if your elevator keeps failing. Evaluate electric currents through your elevator system, and make sure surge protectors are functioning. Test your elevator system to ensure that electricity flows through without problems.

5. Worn Sheaves

Sheaves are pullies with grooved wheels. They hold the ropes and belts that pull and elevator up and down. Sheaves are under a lot of strain, and they wear down with enough use.

Most sheaves become uneven, which can stall the elevator’s movement. Belts can snap or fall off.

If you notice the elevator car is uneven, your sheaves may be worn down. If you notice a sudden jerk while the car is moving, the ropes may have fallen off the sheaves.

Avoid carrying excess weight in your elevator. Heavy loads can strain your sheaves, causing them to break.

The sheaves may need regrooving, allowing them to grip the ropes better. If the sheaves break often, a repair service may need to replace the sheaves entirely. This will require a temporary shutdown of your elevator so the service can make repairs.

Go to the Elevator Installation and Repair Professionals

Elevator installation is complicated and technical. Elevator repair is a little more difficult. You can help the repair process by identifying some common problems.

If your motor makes strange noises, your bearings are malfunctioning. If your motor stops working, metal particles may have entered into your oil.

When you cannot control the speed of your elevator, your motor drive is failing. An electrical outage or broken motor can cause a power failure. If your elevator is uneven, your sheaves may have worn down.

When you need help, get it from the professionals. Island Elevator is Long Island’s leading elevator repair company

Island Elevator is Ready to Help

Island Elevator is here to help you understand all facets of your Elevator Repair, Maintenance, & Modernization costs in the new year. Our team is here to help ensure your home and business vertical transportation equipment receive the regularly scheduled maintenance necessary to help you avoid a major catastrophe, reduce the possibility of a costly repair, and ensure the safety of your passengers, tenants, and family.